Until a few years ago, not many people would have bet on the widespread use of propane as a refrigerant gas for heat pumps. Today, however, thanks to its properties as a natural and “green” refrigerant, there is no manufacturer on the market that has not embraced this new energy transition, and introduced products fitted with propane compressors. Moreover, the use of propane allows heatpumps to work better than traditional refrigerants. On the contrary, it makes the heating, cooling and domestic hot water production system even more environmentally friendly.

A natural refrigerant gas that can help to produce hot water more ecologically. Let’s have a look at the advantages.

A push towards the use of propane came from the European Commission, with the REPowerEU plan aimed at reducing the dependence of EU countries on fossil fuels from outside the EU. The Commission actually sees heat pumps as the key to a crucial decarbonisation of the residential sector, setting itself the ambitious target of installing this technology in 30 million buildings by 2030. A roll-out pace that cannot be separated from the search of more sustainable solutions, especially in the choice of refrigerants used.

Among other things, the new update of the F-Gas Regulation, approved on 16th January by the European Parliament with 457 votes out of 581 in favour, is a step further in banning the use of fluorinated gases in both domestic air conditioners and packaged heat pumps up to 12 kW. For the latter, synthetic gases with a GWP above 150 will only be permitted until 2027, whereas it will be mandatory to use only natural gases by 2032. This means that propane has a very bright future and it will become the main refrigerant for heat pumps up to 16 kW, thanks to its excellent thermodynamic properties and low GWP value.

Low environmental impact

To fully understand the features of propane in relation to environmental friendliness, it is worth comparing it with fluorinated hydrocarbons, the so-called F-Gas, which have been used as reference refrigerants for heat pumps for many years. As we all know, the Global Warming Potential (GWP) is the indicator that helps us define the impact of the emission of a gas on the environment.

Difluoromethane gas (R32), one of the most ecological gases available on the market today and which is used more and more in residential air conditioning systems, has a GWP of 675. This means that every kilogram of R32 emitted into the atmosphere causes an increase in the greenhouse effect identical to that caused by the emission of 675 kg of CO2: an amount of gas that an average-sized vehicle emits when travelling approximately 5,000 km.

Refrigerants that have been in use for a long time, such as R134a or R410a, are even more polluting. Their GWP values are 1,430 and 2,088 respectively, resulting in the emission of 1,430 and 2,088 kg of CO2 for every kilogram of gas that goes into the atmosphere. And propane? As it is a natural gas, its GWP index stands at 3, making it the best possible solution for protecting the environment.

When it comes to a natural gas such as propane, the first question that springs to mind is the issue of safety. Can R290 refrigerant really be considered safe, even for use inside residential buildings? The answer is yes.

The compressors of propane heat pumps are actually designed to prevent any type of gas leakage, just as the refrigeration circuits are watertight, so that there is no contact with the water circuit.

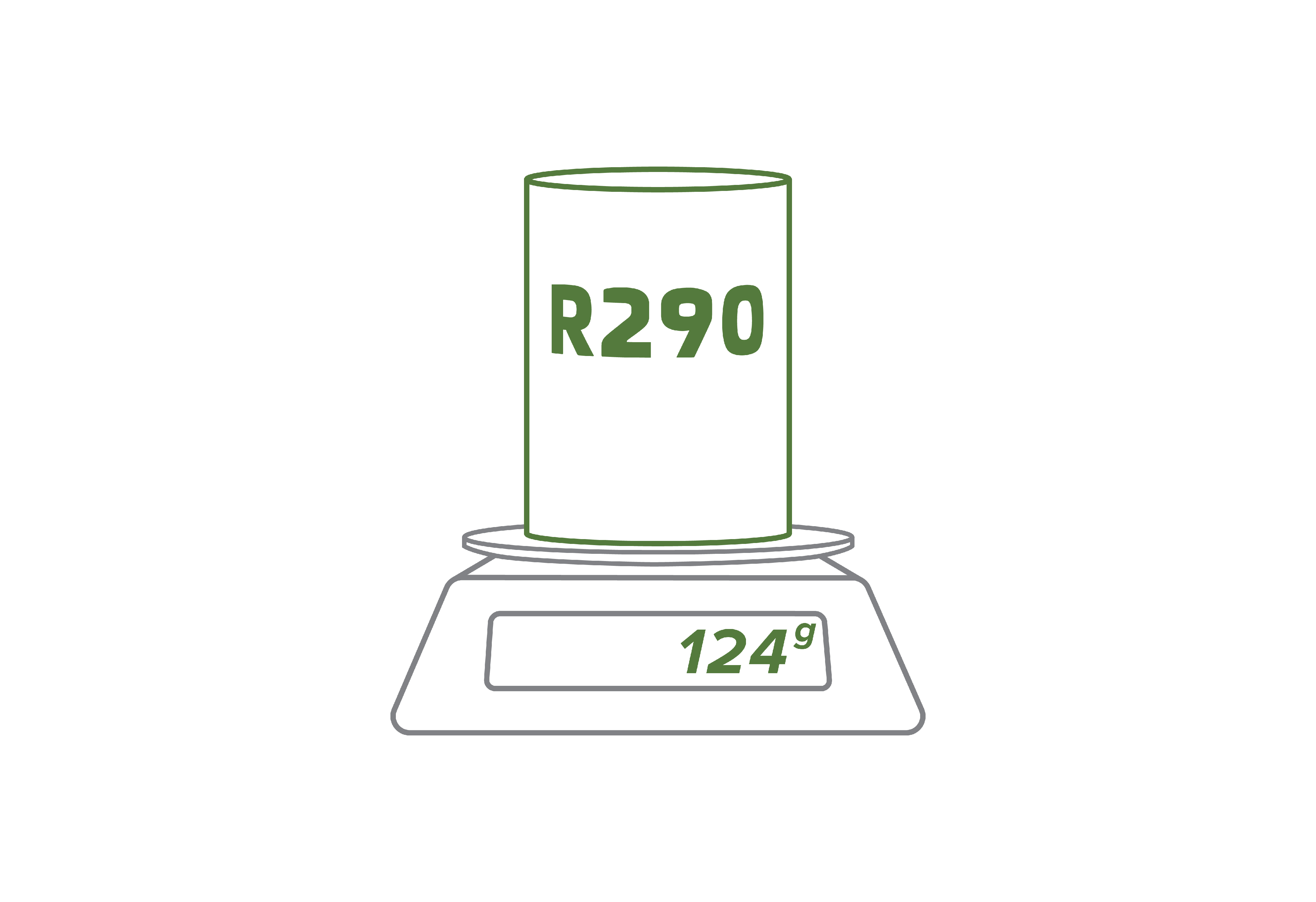

Not only that, the amount of R290 refrigerant used in this type of heat pump is very low. Moreover, the famous German Fraunhofer Institute, in collaboration with some manufacturers, recently conducted a study that demonstrated the possibility of reducing the propane charge to less than 150 grams. As part of the LC150 (Low Charge 150) research project, the Institute developed several prototypes of heat pumps with low refrigerant content. The features of the best one? A heating capacity of 12.8 kilowatts (about 10 kW cooling) with only 124 grams of propane.

The use of R290 refrigerant also ensures greater efficiency and high reliability, thereby ensuring a very high heat transfer fluid temperature, even at extremely low outdoor temperatures. Therefore, propane heat pumps are an excellent alternative to traditional boilers and are the ideal solution in combination with radiators, which, compared to radiant floor systems, require much higher temperatures to heat the house and ensure optimal living comfort.

L’utilizzo di refrigerante R290 assicura anche un’elevata efficienza e grande affidabilità, garantendo una temperatura del fluido termovettore molto elevata, anche con temperature esterne estremamente basse. Pertanto le pompe di calore a propano rappresentano un’ottima

alternativa alle caldaie tradizionali e si confermano la soluzione ideale per un abbinamento con i termosifoni che, rispetto ai sistemi radianti a pavimento, necessitano di temperature molto più alte per riscaldare la casa e garantire un comfort abitativo ottimale.

Always focused on market developments, Clivet has recently launched its first line of packaged heat pumps with R290 refrigerant for residential applications. Edge F is available in 7 different sizes, with power ranging from 4 to 15 kW, and it can reach a supply temperature of 75°C to an outdoor ambient temperature of -10°C.

The improved performance of the Edge F range ensures class A++ in heating at medium temperature (55°C supply water flow) and class A+++ in heating at low temperature (35°C supply water flow), as well as ensuring SEER values of up to 5.86 in cooling.

Other impressive features include a high silence level, with 2 operating modes specially designed to improve acoustic comfort, and a new control system with full-colour graphic interface, which makes using the heat pump even easier and more straightforward.